Interview with Glenn Woodruff of SolarTech Universal, Part 1: Intro to Solartech and Solar’s 3 Worst Enemies

While warm weather is just beginning to thaw out us Midwesterners after a long, cold winter, some of our solar panels come from a much sunnier climate: Riviera Beach, Florida, home of SolarTech Universal.

You can get a quick look inside their manufacturing plant here:

But in addition to this, we want to share with you an in-depth, behind-the-scenes perspective on how SolarTech makes solar panels that fight the three worst enemies of solar: water, heat, and bad policy.

That’s why freelance writer Allison Ruedig had a talk with Glenn Woodruff – native Midwesterner, current Floridian, and senior account manager for SolarTech Universal – who shares his knowledge in this three-part series, “What 3 Things Ruin Solar, and What’s SolarTech Doing About Them?”:

- Intro to SolarTech and Solar’s 3 Worst Enemies (Part 1)

- Defeating Water and Heat (Or, Why Solar Panels Are Like Grilled Cheese and Highways) (Part 2)

- Made In America, By America, For America: How Solar Manufacturing Encourages American Jobs (Part 3)

So for an introduction to Glenn, SolarTech, and those three worst enemies, read on!

(This interview has been edited for brevity and clarity.)

A: We’ve had snow recently in the Midwest, so I’m jealous of you Floridians right now.

Glenn: It’s a beautiful day for solar down here – we have a lot of sun today and it’s around 82 degrees. You’re almost there, though! A couple more weeks…months…

A: That’s how it is – either weeks or months, and you never know which up here.

Glenn: Yeah, I’m from the Midwest myself. I grew up in the Detroit area, so I’m familiar with that weather!

A: You’re lucky to be down in Florida now. Actually, I was surprised to see that SolarTech is the only solar panel manufacturing company in the Sunshine State.

Glenn: In fact, we’re one of the only American-owned solar panel manufacturing companies in the U.S., since many domestically made solar panels are actually manufactured by multi-national Chinese and German companies. For example, one Chinese manufacturer is building a factory almost specifically to supply a big contract. In addition, a Chinese company’s coming into Florida to build a module factory, but it’s for a different application than what we make.

This is good in the long run, because all solar is good solar, in our view.

A: Speaking of expansion, could you say more about SolarTech’s building a new site and adding a second shift?

Glenn: First, let me tell you a little bit about us. We’re a U.S. owned company that assembles our solar panels here in Palm Beach County, Florida.

Check out SolarTech’s intro video here:

And as a U.S. manufacturer, I frequently get the question, “How do you win as a U.S. manufacturer?”

My answer is to always focus on quality materials and innovation, beginning with addressing the three things that are bad for solar:

- Water

- Heat

- Bad policy

We at SolarTech continually innovate to address these three issues. For example, to repel water, we select hydrophobic materials for our panels. We also use Smartwire technology to limit heat within our solar panels. To address the bad policies, we’re members of trade organizations that lobby and educate for better policies. So that’s what we’re about: quality innovation leading to stellar performance.

That’s why our current module offering is named EPIQ, which stands for

- Energy

- Performance

- Innovation

- Quality

That’s our whole mantra of everything we do as an organization.

A: A good mantra. Could you explain more about how SolarTech is expanding?

Glenn: Yes. Our factory here has a highly automated production line (see it in SolarTech’s video here) that makes about 1 module every 90 seconds.

Currently, we’re making about 80 megawatts’ worth of modules a year, enough to power over 12,000 Illinois homes.

In addition to that, we’re now adding a second shift. By the end of the year in this facility, we’ll be running 3 shifts, 24 hours a day, 7 days a week.

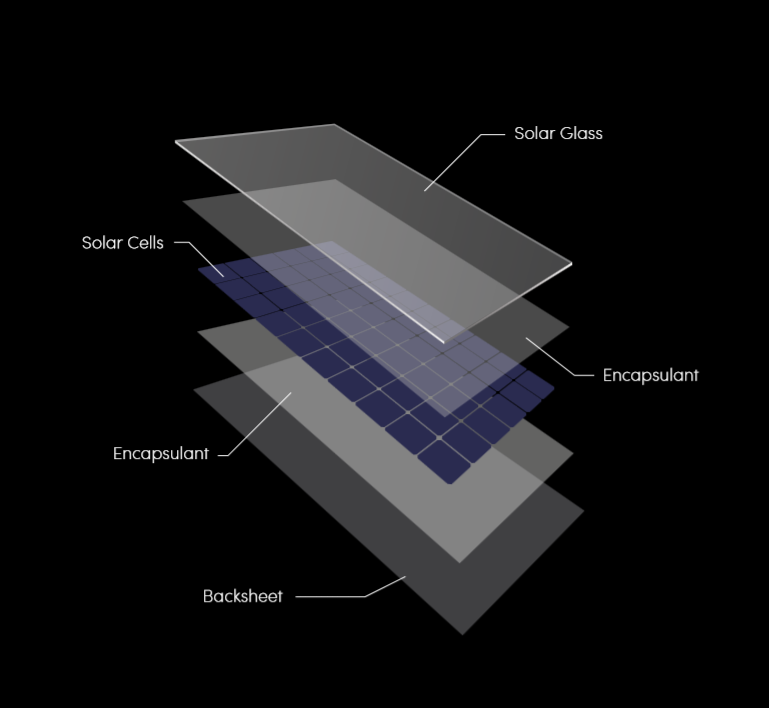

We’ll also be opening a second facility domestically that will increase our capacity threefold. While the panels we make currently in Florid are innovative, some of the panels made in this new facility will be even more cutting-edge. We’ll use bifacial cells laminated between two pieces of glass.

Image credit: solartechuniversal.com

Currently, we apply these bifacial cells to a white or black plastic backsheet. However, our new line’s going to apply them to not only that standard backsheet, but also to a “glass on glass” bifacial model. In the “glass on glass” model, that second layer of glass on the backside acts to replace the plastic backsheet, which will help this model to generate more energy.

Image of an EPIQ solar panel’s elements, courtesy of SolarTech’s EPIQ brochure

So instead of just collecting energy from the front side of the solar panel, these panels can collect more energy from the back as well – between 10% and 30% more.

Here’s some numbers to illustrate:

- If you have a 72-cell module, you can receive close to 400 watts just from the front-side output.

- With bifacial cells and glass-on-glass technology, you receive an additional 10-30% of electricity, depending on the substrate behind the module. A white TPO roof will give closer to 30% extra, a grass field around 20%, and a black parking lot around 10%.

- In the end, your 400-watt module is acting like a 480-watt module.

A: I see what you mean about quality and innovation now!

Glenn: Yes. We at SolarTech are continually asking, “How do we increase the efficiency and the yield of a device?”

And we’ll hear more of SolarTech scientists’ answers to this question in Part 2 of this interview, where Glenn explains several more out-of-the-box but stunningly effective ideas that involve comparisons to grilled cheese sandwiches and highway traffic!

For this crash course in solar technology, and to share your thoughts and comments on solar energy’s three worst enemies, join us on:

- Twitter at @windsolarusa

- Facebook at WindSolarUSA

In the meantime, if you want to explore even more of SolarTech’s creativity, check out their information-filled website at solartechuniversal.com.

And don’t forget that you can get a free solar quote from WindSolarUSA, which installs SolarTech panels across the central Illinois area, by contacting them here, calling them at 217-825-4206, or emailing them at info@windsolarusa.com!

Author:

Allison Ruedig is a freelance writer and editor for businesses creating a greener, more sustainable future. She specializes in solar energy; get in touch with her at linkedin.com/in/allison-ruedig and allisonswords.com!